The warehouse industry does not stand still. As well as keeping track of the numerous moving parts within the operation itself (vehicles, machinery, human employees, and processes), there’s also the challenge of staying on top of compliance.

Safety regulations are constantly updating and evolving, shifting priority and changing in response to new technologies and data from across the warehousing industry; This includes data such as accident statistics, their causes, and the impact on health and safety as well as efficiency.

Take, for example, the recorded high accident rate involving forklifts. These elevated accident risks mean that new, tighter regulation is needed to help warehouse operators prioritize the safety of their workforce and reduce liability for any accidents that do happen. For that to happen, operators will need to adopt and enforce new training and regulations, facing a hefty fine if they’re found not to have had the necessary safety procedures in place.

Maintaining the health and safety of the workforce and avoiding financial penalties are not the only reasons that staying up to date on compliance issues is so important. Compliance also safeguards a company’s reputation as a safe and respectable workplace. There’s also the benefit to operational costs and efficiencies, as avoidable accidents can have huge implications on productivity, fulfilment, and, ultimately, the bottom line.

Why is it important to maintain compliance?

For most, the very idea of not being compliant simply does not compute. The rules are there in plain sight, and so are the penalties and forfeits of not sticking to them

Still, it’s worth getting familiar with the reasons that it’s so important to maintain compliance, and the damage that letting standards slip can cause

Reputational damage

A failure to adhere to compliance is not something that goes undiscovered. Either inspections will uncover that warehouse operators are not conforming to OSHA guidelines and rules, or a post-accident investigation will.

Either way, there will be a ripple effect as the circumstances of the breach become known and published alongside penalties, and reputational damage is inevitable. Employees do not want to work at a site where their health and safety are not prioritized. Likewise, customers are less likely to want to trust their work to an operation that flaunts regulations, either because of the reputational damage or the impact that avoidable incidents can so easily have on productivity and long-term costs.

Ensuring smooth operations

As well as ensuring the best health and safety outcomes, compliance also works to ensure that operations run smoothly. Accidents are disruptive by their very nature, taking assets out of use and disrupting the efficient flow of work.

Whether that’s by personal injury, vehicles being taken in for repairs, or stock being damaged or lost, an incident’s impact on a warehouse operation’s ability to function can be serious and potentially lengthy. Compliance helps to make sure these occurrences are as infrequent as possible.

Preventing fines

Downtime and injury aren’t the only ways that a lack of compliance can cost warehouse operators money, there’s also the very real possibility of being fined by OSHA.

OSHA (or Occupational Safety and Health Administration) is the US regulatory agency in charge of keeping workplaces safe and conducive to good health.

With this remit, they have the power to issue hefty fines of anywhere between $16,550 and $165,514 per incident. It’s not an idle threat either, as OSHA is dedicated to issuing fines to any organization that breaches its standards. In 2023 alone, OSHA handed Amazon fines totalling almost $6 million for the retail giant’s disregard for compliance,

Maintaining employee satisfaction

Between 2011 and 2023, the number of warehouse and distribution employees increased from 668,000 to 1.9 million. That’s a huge jump, and one that saw labor rise to become the largest single fulfilment cost warehouses face.

The following labor crunch means that it’s more important than ever to keep staff turnover low and hold on to skilled workers, especially when it takes around a quarter of an individual’s salary to find and train up a replacement.

All of which is why it’s so important for warehouse operators to make sure that employees are satisfied that their health and safety is a top priority. Without that confidence, they will go elsewhere.

Breaking down the key compliance challenges

For warehouses adhering to compliance regulations, there are several areas of concern.

- Licensing – All vehicles used for goods and transportation have to have valid documentation, as per the Motor Vehicle Act of 1939, such as a warehouse license from the local authority or Municipal Corporation.

- Training – With compliance rules and regulations changing frequently, it’s of paramount importance that warehouse operators provide staff with the latest knowledge and skills through specific training.

- Certification – Acquiring certification is a warehouse operator’s chance to prove that they are taking compliance seriously, and taking regulations onboard. Programs such as the LSIB’s Certificate in Warehouse Safety and Compliance cover OSHA regulations relating to forklift operations, security, material handling, and more.

- Inspections – OSHA has the prerogative to inspect workplaces when they deem necessary, usually as a result of complaints. Warehouse operators will be notified of OSHA’s intent before an inspector conducts a walk-around of the site, making notes and observations. If operators want to avoid fines, they must show that there are no compliance breaches.

How can Powerfleet help overcome these compliance challenges?

Maintaining compliance across warehouse operations can be a time-consuming task. By using Powerfleet products, warehouses have access to safety features and insights that work to actively and passively keep employees safe across the site.

Electronic safety inspections

Electronic safety inspections are incredibly versatile. For a start, they guarantee regulatory compliance and vehicle maintenance, while also being completely paperless.

Configurable and event-based, any impact will automatically trigger a checklist for either the supervisor or driver, depending on severity.

Electronic safety inspections also provide useful prompts, such as reminding drivers to stop and park a vehicle before shutdown, while vehicle telematics promote pre-emptive maintenance.

Impact management

Using a combination of sensors, accelerometers and more, Powerfleet’s impact management system reduces collisions while also providing useful insights when they do occur.

A machine learning algorithm automatically and continuously calibrates set point readjustment, while real-time notifications and feedback coach vehicle drivers as they work.

In the event of a collision, the impact management system is connected to an external alarm to alert supervisors, with a black box recording giving insights into the vehicle’s performance before, during, and after a collision.

DVR and impact-triggered recording

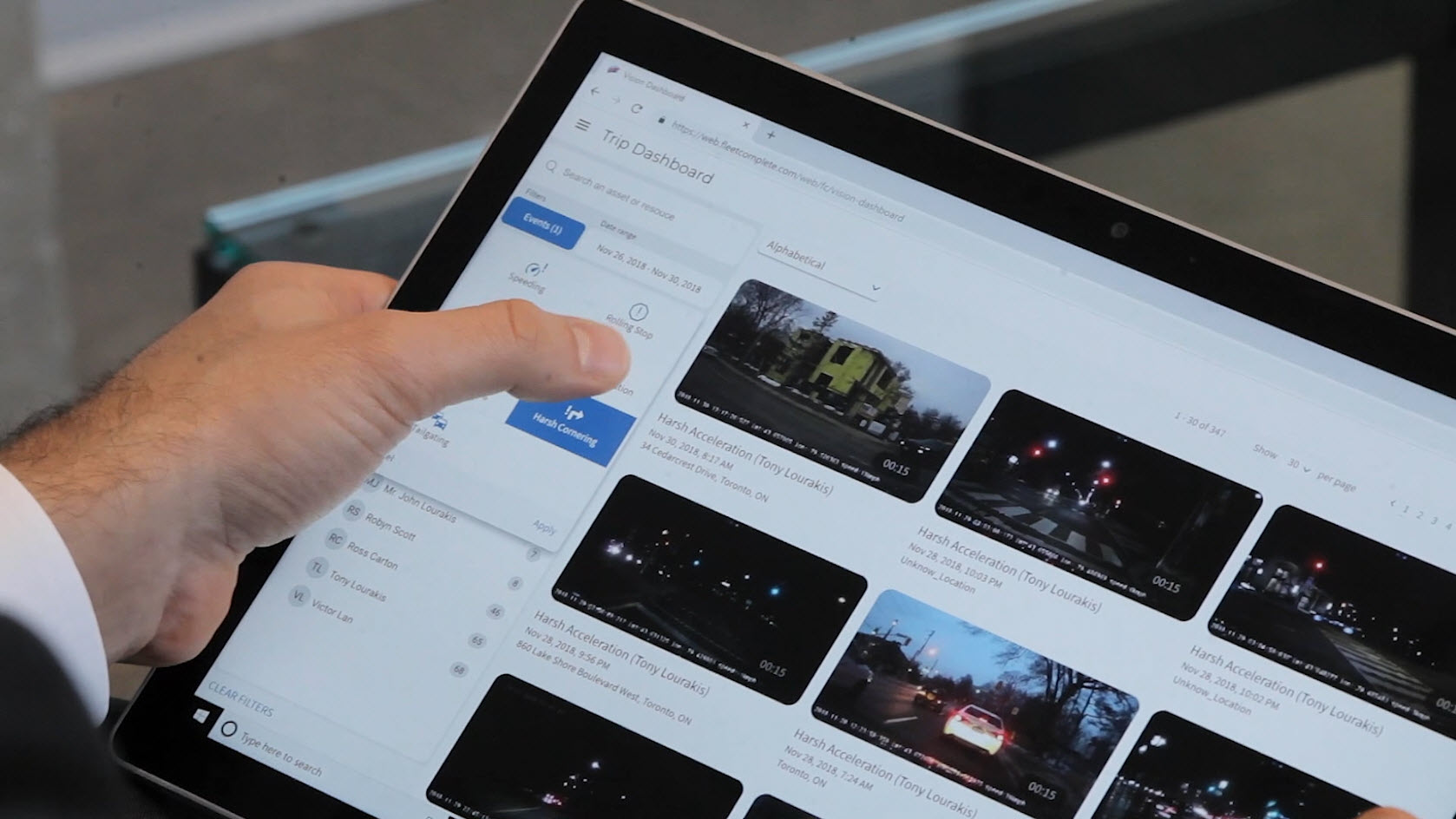

Using four cameras and a centralized DVR, video from around forklifts and other vehicles is captured and stored on an SD card.

The DVR collects video clips of before and after an incident, whether it’s speeding, a collision, or a prompt given to the driver, thanks to its connection to Powerfleet’s Forklift Gateway system.

With the insights the cameras and DVR yield, it’s easier than ever to view and assess the circumstances that led to an incident, ensuring compliance was observed and putting measures in place to stop the same from happening again.

Pedestrian proximity detection

Powerfleet’s Pedestrian Proximity Detection (PPD) system actively increases safety on the warehouse floor.

The PPD warns drivers of nearby obstacles, identifying high-risk obstructions such as people and other vehicles on their route, thanks to an AI-based vision system that doesn’t rely on wearable RFID or IoT tags.

The PPD also feeds into the Forklift Gateway (VAC) through a Sensor Hub, giving further insights through fleet telematics.

How Xerox relies on Powerfleet for compliance

The world’s leading document management, technology and services company, the Xerox Corporation is a true global juggernaut with over 100 distribution centers.

The team at Xerox’s Groveport, DC, warehouse identified key areas where a warehouse management solution, such as Powerfleet, would improve compliance. These included automated vehicle checklists for OSHA compliance, as well as vehicle access and limitations.

This concern had proven difficult for Xerox to enforce previously, but Powerfleet’s dashboard makes it easy to restrict any driver from controlling a vehicle until they have the necessary, up-to-date certification.

Xerox also wanted to move away from its manual, paper-based vehicle safety checklists. These checklists had to be completed for each vehicle, daily, and were a drain on management’s time.

With manual checklists, operator compliance was extremely difficult to verify, with checklists not being updated in good time, while OSHA compliance dictated that years’ worth of completed checklists had to be stored and made available onsite.

Powerfleet prompts vehicle operators to complete a checklist or be locked out of the vehicle. Checklist results are stored digitally, operator accountability is increased, and management is alerted if the checklist is not completed.

Since implementation, the Xerox warehouse in Groveport can now ensure a 100% compliance rate for pre-shift checklist completion.

Powerfleet can improve your warehouse compliance. Request a demo today.