Security cameras don’t just exist to deter vandals and capture robbers in the act. When it comes to warehouse operations, they’re a vital part of the safety apparatus.

By using a combination of mounted cameras and motion detection, it’s possible to create a safer environment for pedestrians and fleet vehicle operators.

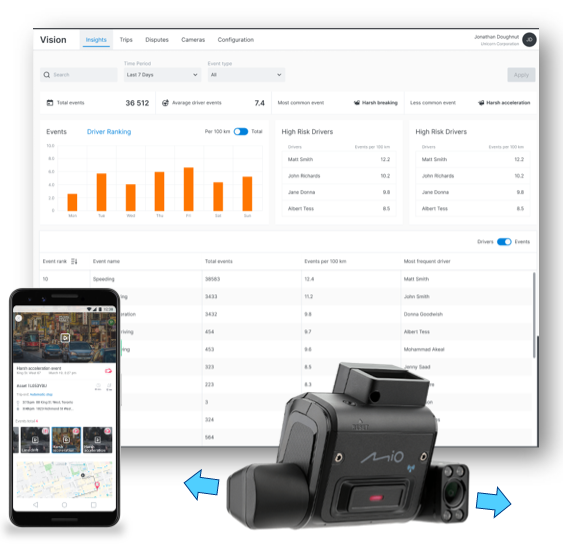

That’s how Powerfleet utilizes cameras. Alongside vehicle telemetry, our event-triggered digital video recorder system not only reduces the chance of accidents, it also gives warehouses the chance to learn from incidents.

By automatically capturing real-time video of impacts and accidents, the event-triggered digital video recorder gives you a comprehensive record of what happened before, during and after an incident. With those insights, it’s possible to deconstruct events, update and clarify safety training and procedures, and even resolve any cases where there is a question of liability. All thanks to unimpeachably accurate data.

Using security cameras to improve warehouse safety

When it comes to cameras in warehouses, capturing incidents as they happen is just half of the story.

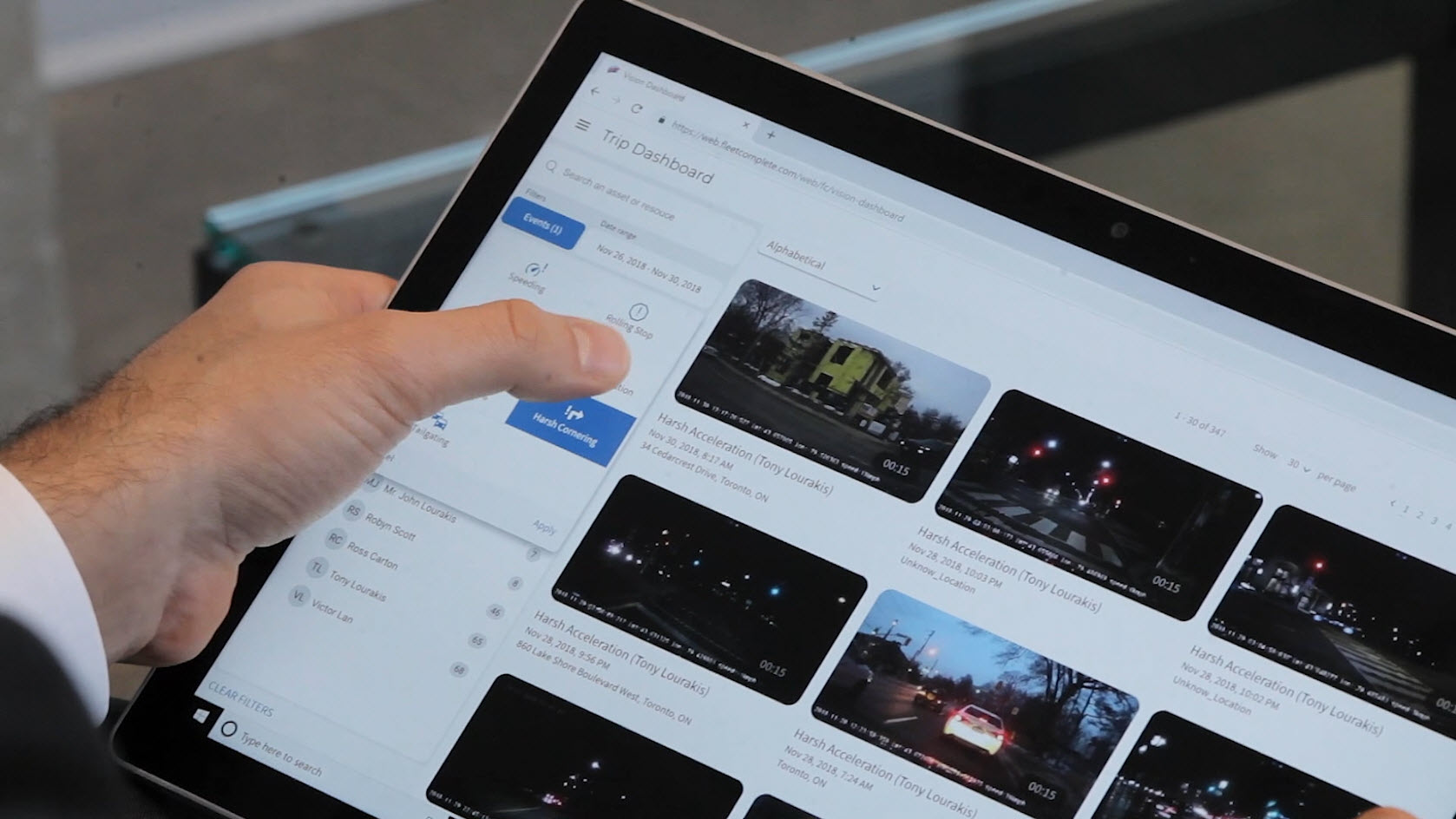

In reality, what comes next, how the video data is used after the fact, is arguably where camera systems really prove their worth. Any incident in a warehouse is going to lead to a reassessment of safety procedures.

What guidelines were adhered to, what safety protocols were ignored or lapsed, and which processes need to be changed and updated to stop similar incidents from happening in the future. Video footage from security can show all of this and more, allowing warehouse operators to travel backwards through events, pinpointing the exact circumstances that led to an accident.

Here’s how security cameras can be used to improve warehouse operations:

Safety training

Sometimes, certain accidents happen for the first time, either as a result of new equipment or processes, or staff who have different experiences and training. Whatever the reason, the footage from security cameras (both in the warehouse and mounted to vehicles like forklifts) become an invaluable source of data for staff training.

By demonstrating what went wrong, and how, you can create new safety processes that will stop it from happening again. Not all safety training is based on hypothetical situations; some of the most effective training actually comes from a need to stop accidents from happening twice.

Importance for insurance & liability claims

Any incident or injury in a warehouse is going to come to the attention of legal teams. If a vehicle or stock is damaged, then insurance companies will need to know exactly what happened and who was to blame. That becomes even more important when an employee is injured.

In these cases, video cameras are vital for establishing liability. Who was at fault for the accident? The driver? The pedestrian? Or is it the warehouse operator’s ultimate responsibility for not putting the necessary safety precautions and training in place? Whatever the case, security cameras offer a clear picture of what happened and why, helping to settle any claims quickly and decisively.

Bolstering Health & Safety practices

Both of the above examples rely on cameras to capture an event, or a series of events, and report back, but cameras can also be a preventative health and safety tool. Camera feeds are able to provide a glimpse into areas beyond obstructions or simply around corners. They can give the full picture of a route, rather than just what is in the line of sight.

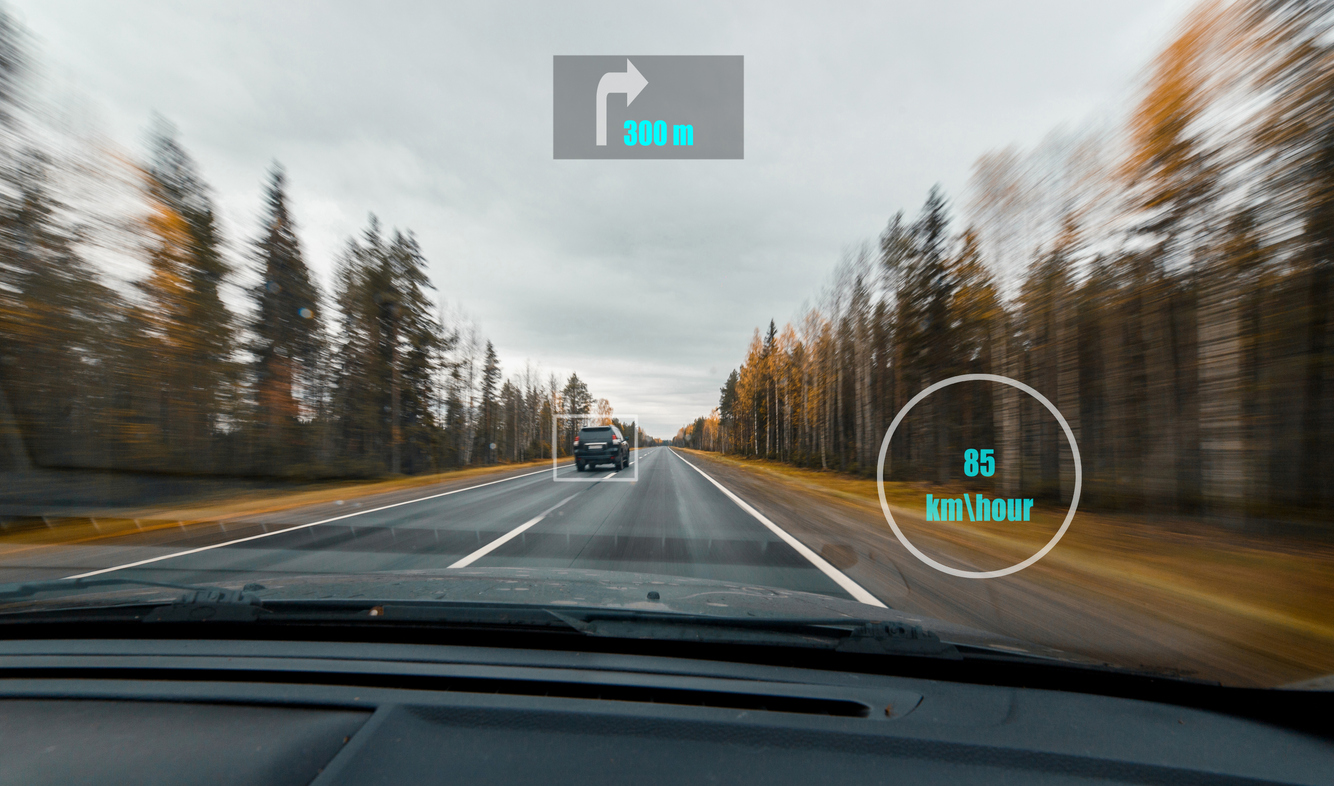

More than that, though, the cameras can use AI and IoT technology to identify hazards, such as other vehicles, obstacles, and pedestrians, and take action. It’s even possible to slow a vehicle automatically based on what cameras and sensors detect, guiding the forklift through hazardous areas and away from potential collisions for proactive health and safety. In fact, that’s one of the capabilities that Powerfleet puts into your hands.

How do Powerfleet Solutions use Digital Cameras?

Powerfleet uses powerful digital cameras to improve health and safety, as well as reporting for warehouse operations, it’s true. But that’s only part of the story, not the full picture. The cameras connect and streamline the entire warehouse operation, using integration and AI-driven in-warehouse solutions to improve efficiency, safety, and productivity.

With real-time monitoring and reporting, predictive insights, and fleet telematics, you’ll always have the data you need at your fingertips. And thanks to access control, speed management, and preventative maintenance capabilities, it’s easier than ever to keep productivity high by eliminating unexpected downtime from area closures and vehicle damage caused by equipment misuse or accidents.

Powerfleet’s in-warehouse solutions accomplish all this by drawing on the award-winning Unity data intelligence platform. Using Unity, Powerfleet can seamlessly integrate AI processes, IoT devices, and third-party systems and datasets from across the entire warehousing operation. Unity and Powerfleet put all that data and control in one place, giving you a 360-degree, 24/7 view of everything that happens in your warehouse 24/7,

So, where do security cameras factor into this groundbreaking system?

Event-Triggered Digital Video Recorder

The warehouse is a dangerous environment, so no matter how closely you stick to OSHA’s guidelines, or how much you’ve invested in preventative measures and training, accidents are going to happen at some point.

Telematics and collision detection technology like Powerfleet’s will make it less likely and help you learn from incidents as they happen. To do that, you need an event-triggered digital video recorder.

Powerfleet’s event-triggered digital recorder system uses four cameras and a central DVR hooked up to each forklift and vehicle, capturing real-time video across an entire journey. Easy to cycle through and transfer, the video data gives warehouse operators a comprehensive view of whatever has happened. Once you have that, new safety measures and training can be put in place to minimize the risk of it happening again.

Pedestrian proximity detection

Powerfleet’s pedestrian proximity detection and avoidance technology acts as a powerful last resort. When blindspots, turning circles, and unpredictable movements hamper a forklift operator’s ability to keep everyone safe, the pedestrian proximity detection system steps in.

Using front and reverse cameras and a vision system that doesn’t rely on wearable IoT or RFID tags, pedestrian proximity detection identifies vehicles, pedestrians, and other hazards to keep employees safe at all times.

Forklift speed manager

As we mentioned earlier, the forklift speed manager is able to take control of a vehicle’s speed as it passes through hazardous areas, either through pre-programming or in response to developing situations.

That last scenario is where cameras come into play. Backed up by mounted sensors. Powerfleet’s cameras can identify obstacles and pedestrians without the need for IoT or RFID tags. Instead, Powerfleet’s vision-based system recognises the obstacle and alerts the telematics system. That activates the forklift speed manager, stopping accidents before they have a chance to happen.

Powerfleet’s cameras can improve your warehouse operation

Regardless of how many IoT sensors and AI processes you have in your warehousing operation, Powerfleet brings them all together in one easy-to-manage platform.

Security cameras also bring in a huge part of the data that helps warehouses thrive, capturing vital moments and providing valuable context behind incidents, context that can be used to make sure they don’t happen again, and that liability rests in the right place.

To find out how Powerfleet and its innovative use of cameras can make your warehouse safer, book a demo today.