The warehouse environment never stands still for long; it’s always evolving. New technology enters the workplace, new systems take over various operations, and new training and guidance are needed to keep up with it all.

Every year, the way that warehouses operate changes, and it’s the job of the Occupational Safety and Health Administration (OSHA) to ensure that workplaces operate in a way that prioritises warehouse health and safety requirements.

OSHA was formed in 1971 in the wake of the Occupational Safety and Health Act. A federal agency with a wide remit, OSHA is responsible for ensuring that employers provide safe and healthy working conditions for employees.

To that end, OSHA issues a series of warehouse health and safety regulations that employers must adhere to by law. While these laws are frequently updated to address new challenges, some elements are universal and are likely to not change.

By issuing standardized regulations and penalties, OSHA not only protects workers in warehouses and other environments but also tacitly helps workplaces to avoid the loss of productivity and earnings that serious incidents, temporary shutdowns, and permanent closures bring. And closure is within OSHA’s power after repeated violations of warehouse health and safety requirements.

What are the key US warehouse health and safety requirements?

OSHA regulations apply to almost every single workplace in the USA, not just warehouses. Because of that, there are a number of standard regulations that apply to all workplaces, as well as specific warehouse rules.

For example, all employers must:

- Provide each employee with the necessary and appropriate personal protective equipment (PPE)

- Arrange suitable safety training for all employees, either in-house or through external facilitators, to help them deal with potential hazards in the workplace.

- Keep all workspaces and areas clean, sanitary, and orderly

- Ensure all surfaces that support workers, equipment, or machinery are strong and not at risk of collapse

- Guarantee that workspaces are free of hazards such as sharp objects, liquid spills, loose flooring, and more

- Keep entry and exit points safe and clear

- Regularly inspect and maintain work areas

- Address hazards before allowing access to the affected area.

- Keep portable fire extinguishers ready and available

Warehouses are highly specialised workplaces, and so OSHA has additional standards for the hazards warehouse workers face, including:

- Ladders, stairways, and other elevated surfaces

- Falling object protection

- Preventing falls from heights

- Safeguards and maintenance for exit routes

- Ventilation plans

- Maintaining safe levels of occupational noise

- Managing and disposing of hazardous materials

- Regulations for the use of heavy machinery, such as forklifts

- Hazardous area communication protocols

- Ensuring rest breaks

- Providing relevant training for machinery and environments.

Depending on the severity of the OSHA violation, warehouses can be fined between $16,550 and $165,514 per incident, a figure which has risen as part of this year’s updates.

What are the changes to US warehouse health and safety regulations in 2025?

The most recent raft of changes to OSHA’s warehouse health and safety regulations are widely preventative in nature. There’s a real focus on safer working environments, building a culture of safety as second nature, and creating more efficient warehouse operations as a result.

As such, inspections will be carried out with a greater frequency, and there’s even talk of limitations being placed on production demands to better protect employee health.

OSHA’s updates for 2025 specifically outline the importance of equipment fit across the board (more on that later), enhanced protections for delivery workers, working with technological advancements, and ensuring the safety of workers in hot environments.

As it stands, the following changes to OSHA have been confirmed or proposed for 2025, but there is always the possibility of more regulations being put in place before the end of the year to further enhance workplace safety standards.

The confirmed changes to OSHA’s regulations for warehouses include:

Equipment fit

One of the biggest overhauls to OSHA’s standards in 2025 affects equipment fit and the frequency of compliance inspections. What do we mean by equipment fit? Basically, the new and updated regulation means that every piece of equipment that a worker interacts with, from safety harnesses to the seat of a forklift truck, must be suitable for the body shape and physique of the entire workforce.

It’s a preventative measure that has been designed to reduce the risk of misuse and injury, either through accidents or long-term side effects, such as muscle aches, joint weaknesses, and musculoskeletal injuries.

Warehouses that do not adhere to the new warehouse rules on equipment fit standards risk heavy penalties, especially as each infraction is penalized individually. Amazon has recently been on the receiving end of OSHA’s wrath, with a series of safety violations and lack of compliance leading to fines of almost $6 million in 2023 alone.

The scale of Amazon’s fines should be a stark reminder to warehouses of all sizes to prioritize health and safety for employees, especially as the OSHA updates come with even more rigorous inspection protocols and greater consequences.

Protecting workers from heat-related illnesses

One of the proposed changes to OSHA warehouse rules and regulations is a rule that gives workers greater protection from heat and heat-related illnesses.

Designed for both indoor and outdoor workspaces, the new requirement will see employers compelled to offer water and rest breaks, as well as shaded and/or air-conditioned areas when the temperature exceeds an acceptable level.

The proposal has not yet been finalized, but it is also likely to make employers responsible for providing heat-illness training to workers (so that they can recognise various symptoms, and offer aid), as well as developing Heat Injury and Illness Prevention Plans (HIIPP).

National Emphasis Program (NEP) on Warehousing and Distribution

Although launched in 2024, OSHA’s National Emphasis Program (NEP) was designed to focus on the warehousing and distribution industries (including retail and ecommerce, local delivery, and mail and parcel processing services) over a three-year period.

Focusing on preventative measures, the NEP sees an increase in safety inspections taking place at warehouses and distribution centres. Exits and entrances, fire protection, walking surfaces, material handling, and the operation of forklift trucks all fall under its remit.

How do Powerfleet Solutions help maintain US warehouse health and safety compliance?

When it comes to forklift safety, Powerfleet has you covered thanks to a range of IoT and telematics systems that keep the working environment safe at all times.

The OSHA guidelines and regulations give employers and warehouse operators a base-level safety requirement, but Powerfleet’s in-warehouse solutions elevate pedestrian and forklift operator safety to a consistently high level.

Here’s how we help you keep your adhere to warehouse safety regulations, keeping employees safe from forklift-related accidents and injuries.

Forklift Speed Manager

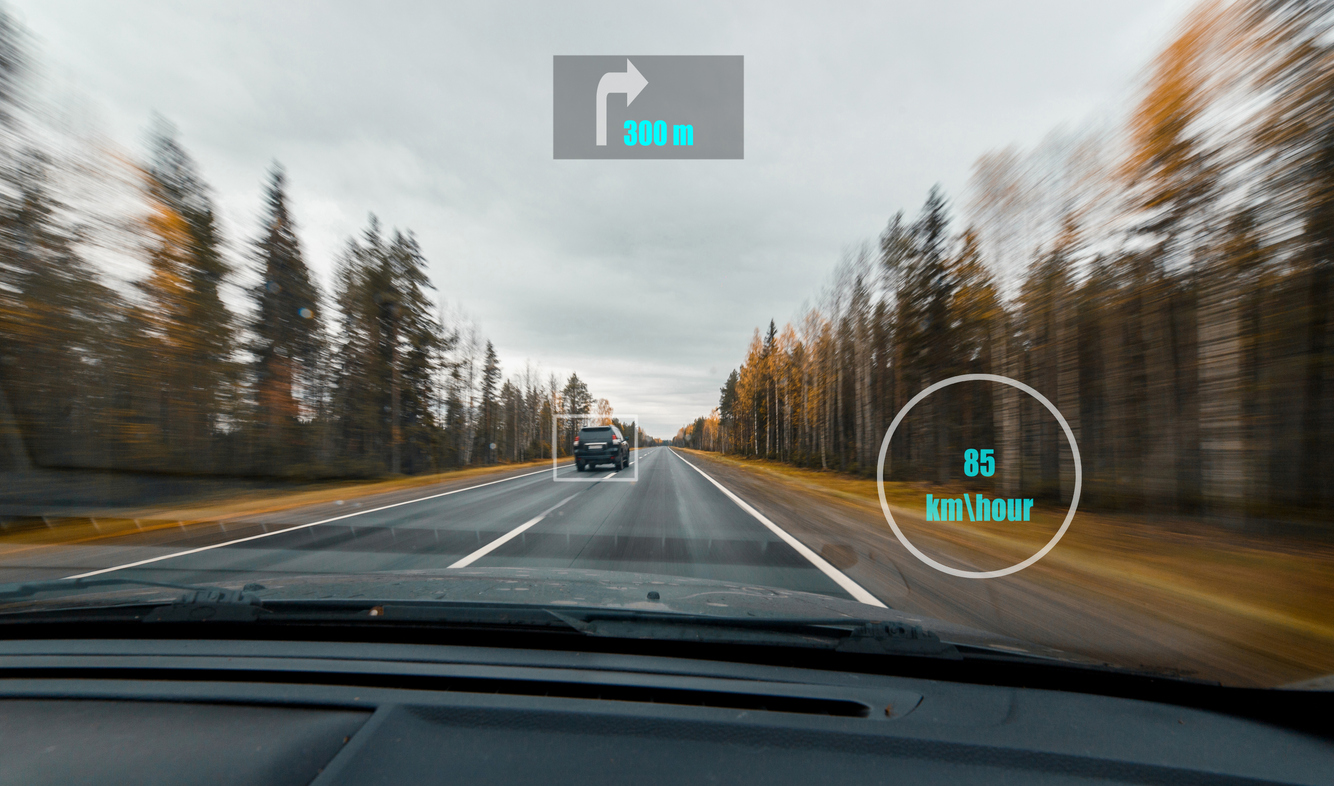

By attaching sensors to your forklift fleet, you can automate certain safety features. For example, the externally mounted sensors will register external conditions and react accordingly, slowing the vehicle in the face of threats or as it navigates through certain high-risk areas.

With this extra element of control, Forklift Speed Manager lowers the chances of accidents occurring due to unsuitable driving or driver inattentiveness.

Pedestrian Proximity Detection

You can’t always rely on line of sight and quick reflexes alone. Turning circles and the presence of blind spots mean that accidents can still happen and people can still sustain injuries.

With Powerfleet’s Pedestrian Proximity Detection system, drivers are instantly alerted to nearby hazards. By using a vision system that can identify other vehicles and pedestrians, there’s no need for wearable IoT or RFID tags. Instead, the Pedestrian Proximity Detection system is always working to keep employees safe on the warehouse floor.

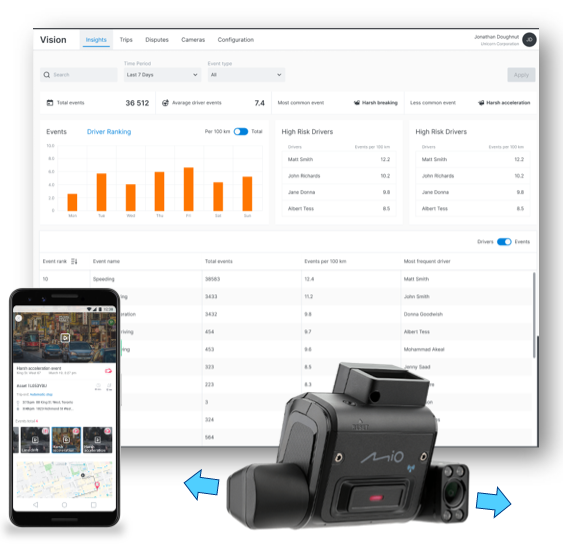

Event-Triggered Digital Video Recorder

Even with the most advanced telematics and collision detection technology installed on your forklift fleet (not to mention a stringent adherence to OSHA regulations), accidents can still happen. Warehouses are an inherently dangerous workplace, and it’s impossible to completely negate that risk. What you can do though, is learn from incidents to make sure the same thing never happens again.

With four cameras and a centralized DVR, Powerfleet’s event-triggered digital video recorders capture incidents as they happen. With that footage, employers have the power to review exactly what happened and, more importantly, why. Once that’s done, it’s easier than ever to put new measures in place, such as training and guidance, that ensures an even safer working environment going forward.

Protect your employees and warehouse operations with Powerfleet

With new OSHA guidelines and greater inspections coming into force, it’s time for warehouses to re-evaluate their forklift safety measures.

Using the latest technology, Powerfleet’s in-warehose solutions give you the opportunity to reduce forklift accidents, thanks to enhanced safety features and incident capture technology. Alongside the updated OSHA regulations, Powerfleet makes your warehouse the safest possible environment.

Want to learn more

Request a demo today, and see what Powerfleet can do for your warehouse operation and employees.