The success of a construction project relies on equipment, building materials, and teams being at the right place at the right time. Hauling lumber, concrete, steel, drywall, and other building materials to construction sites requires heavy-duty commercial trucks to help projects get completed on time and within budget.

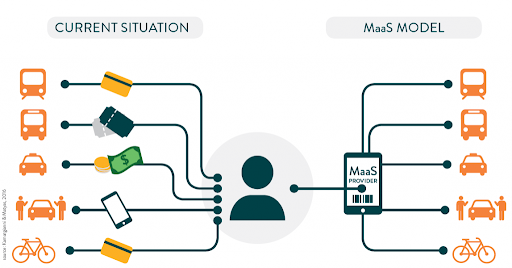

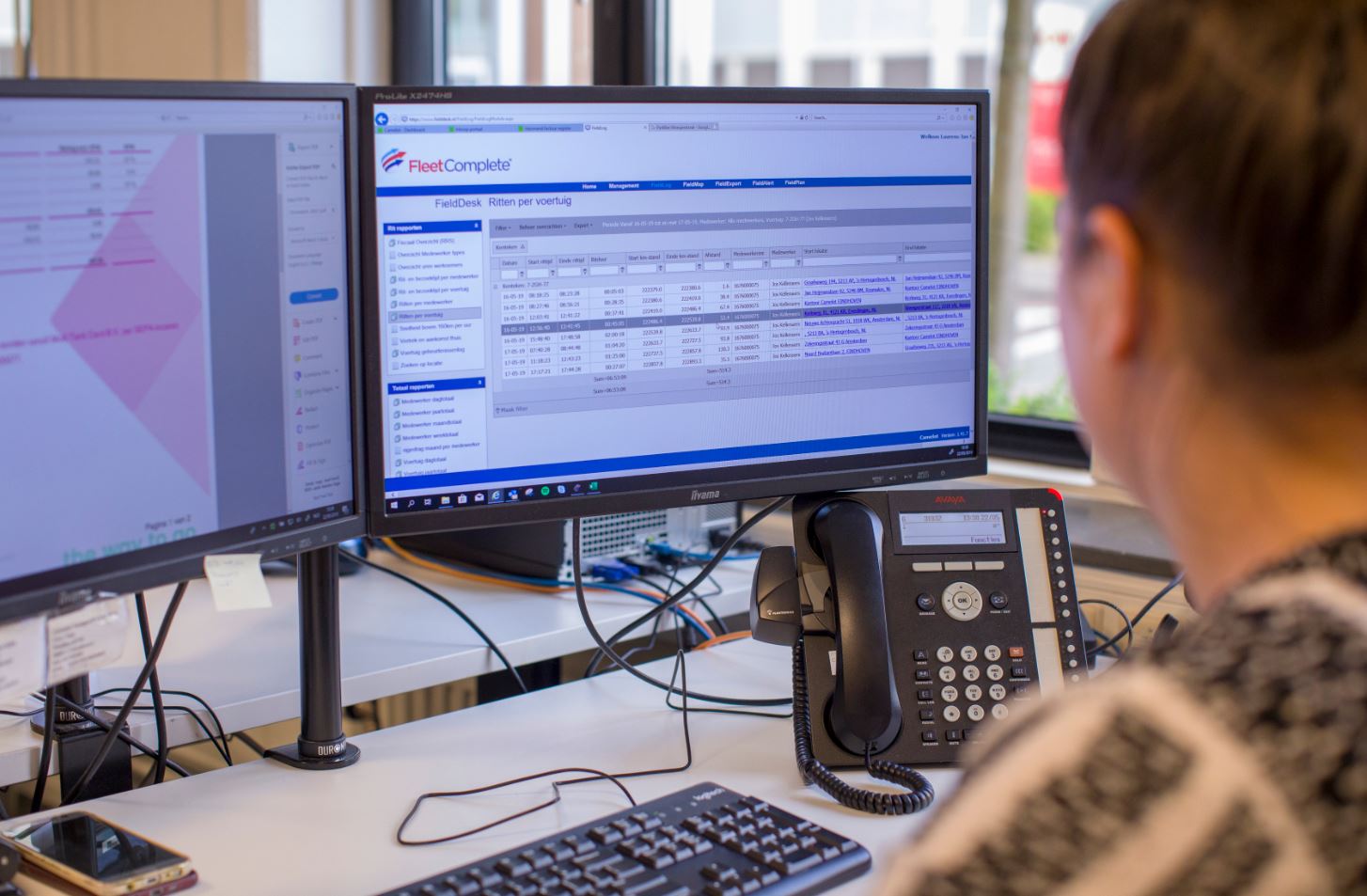

With the help of fleet management software, projects can be completed on time, safely and with the least amount of resources needed. Keeping general contractors, engineers, and project managers up to date on where materials are, and when they will arrive is crucial to keeping projects on schedule, as delays can lead to litigation and reputational damage.

Labor Shortages in the Construction Industry

A leading challenge the construction industry faces is the need for more skilled workers. The U.S. construction industry has a shortage of half a million workers, and contractors can’t afford to wait for materials and equipment to arrive. According to the Canadian Construction Association, Canada also has a shortage of around 93,000 tradespeople, and 22 percent of existing workers are due to retire by 2028.

Many businesses are looking to technology to compensate for the labor shortage. This is where fleet management software can help – providing near real-time insight on equipment resources to optimize efficiency.

The Importance of Fleet Management Software to Construction Firms

Before materials arrive at the construction site, and throughout the project, construction equipment is hard at work grading lots, digging foundations, mixing concrete, and transporting pallets of materials to where they are needed. Construction companies must carefully schedule and prioritize their assets around swiftly changing circumstances. A digital fleet management platform is essential to keeping construction projects and materials moving forward efficiently.

Effective construction fleet management requires software and connected devices that can monitor the location and productivity of construction vehicles, assets, and cargo in near real time. Construction crews need to ensure construction sites are secure around the clock due to the inherent risks associated with building new residential and commercial buildings.

What is Asset Management in the Construction Industry?

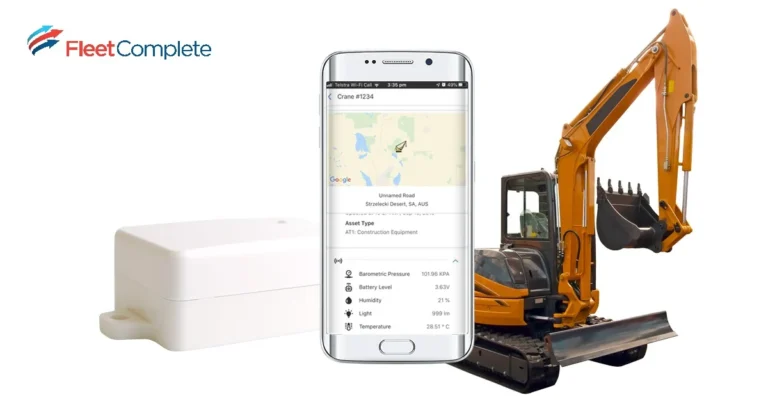

The availability and mechanical fitness of “yellow iron” assets like graders, excavators, bulldozers, and dump trucks are critical to keeping construction projects running on schedule.

Many construction vehicles and equipment have similar engines and electronic control modules (ECMs) to conventional trucks, and companies can monitor asset health through the OBDII port to get alerts and information about maintenance schedules.

Ensuring heavy equipment like bulldozers and front loaders work efficiently requires a strict regimen of preventative maintenance and close monitoring to avoid costly repairs. By mitigating repairs and extending vehicle life, a business can easily maximize its return on investment in a fleet management software platform.

Leading Benefits of Construction Fleet Management

Extend Equipment Service Life

A Construction Equipment Magazine survey found that the demand for new equipment was lighter than usual in 2022. Due to supply chain issues, that contradicts the perspective of construction equipment buyers and managers, who report they had difficulty finding the machines they needed last year.

They have to find new ways to extend the service life of equipment assets and vehicles. Fleet management technology helps operations managers to better track preventative maintenance activities and keep construction assets running for longer than in years past. That said, some equipment is aging past what equipment managers feel is healthy, so that and replacing that gear will be prioritized this year.

The results from a recent survey forecasts this year’s construction fleet expansion rate should be around 26.5 percent for large fleets and about 12 percent for small ones. Two-thirds of the fleets surveyed said they planned to keep their fleet at the same size or downsize their assets based on current utilization. 44 percent said they have increased their maintenance budgets for 2023 to keep their equipment productive in the field.

Mitigate Theft and Unauthorized Use

Due to sparse equipment availability, and the high cost of construction equipment, millions of dollars worth of equipment, supplies, and tools go missing every year. On average, only 25% of stolen equipment gets recovered. Yet some construction companies like Anglia Steel often credit their connected devices and fleet tracking software as their best defense against theft and to recover equipment in the event an asset is stolen.

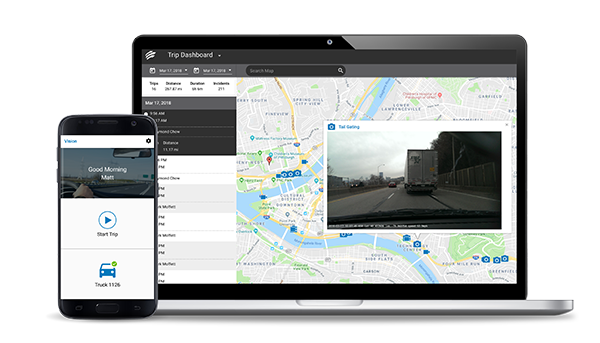

To avoid these problems, It is vital to oversee vehicle and equipment asset use during business hours and monitor their security at night. Telematics devices and sensors can detect job site and equipment intrusion faster than any human security guard.

Improve Customer Relations

Whether your company is building a skyscraper, a hospital, or a multitenant residential building, investors have a lot at stake. A fleet management platform can add credibility and precision to client conversations about construction logistics. Leading fleet management software platforms can also enable construction companies to provide customers with self-service access to delivery tracking within a secure fleet portal.

A telematics device enables fleet managers to track when vehicles enter or leave a geofence zone. Monitoring where material and equipment are in real time eliminates the need to call drivers for ETAs since the latest information is easily accessible through the software.

Fleet management can streamline invoice creation and billing processes when specialized equipment like concrete mixers or cranes are billed by the hour. Accurate billing and up-to-the-minute fleet oversight instill client confidence.

Safety and Compliance

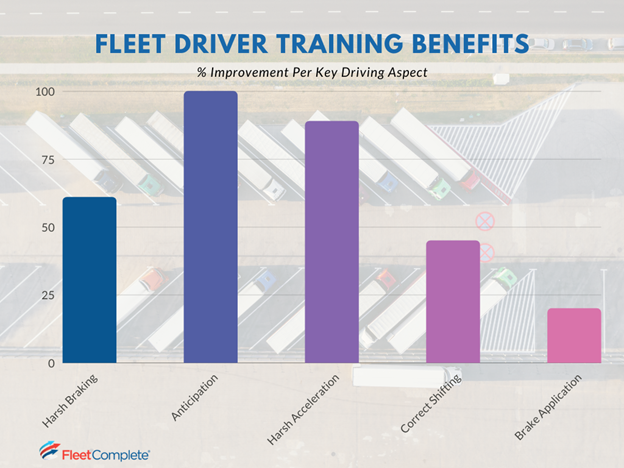

Smart dash cameras, in-cabin policy violation alerts, and recorded video help keep construction personnel safe while behind the wheel. They help detect activities like texting while driving and hazardous road conditions. Preventing injury and collisions on the road or around the job site mitigates downtime, productivity loss, and client frustration.

A positive safety record is a key ingredient to driver retention. Two other ways a fleet management solution can help you stay compliant include:

Fleet Reports

Fleet management platforms generate many of the reports that government agencies require from construction companies as they relate to:

- Safety inspections

- Fuel taxes (IFTA)

- Environmental matters such as carbon emissions

- Miles traveled

- Incident reports following collisions

The penalties for non-compliance with these government mandates can be very costly, and can make prevent drivers and companies from renewing their licenses and contracts.

ELD and HoS Guidelines

In many places across the globe, heavy-duty truck drivers must comply with their jurisdiction’s electronic logging device (ELD) and Hours of Service (HoS) mandates. Investing in a mobile-friendly fleet management platform that incorporates GPS vehicle track and trace along with compliance reports in a single platform increases employee efficiency when they are on the road, sourcing materials or onsite.

The Current State of Construction Fleet Management

The ConstructionFleet Magazine survey cited above found that construction fleet health deteriorated in 2022, and only the largest fleets expect contract volume and value to increase this year.

Due to supply chain issues, many fleet equipment managers have found it challenging to get the equipment they needed to grow their fleet over the past couple of years. Many order lead times extend into 2024, forcing fleets to keep their equipment in longer active use than they would when supply chains ran more efficiently.

It is an ideal time for construction companies working on American infrastructure projects to invest in advanced construction. The U.S. government has set up a $100 million fund for construction management technology, including telematics.

Internet of Things (IoT) Sensors are Vital on Construction Sites

Monitoring a modern construction fleet is most effective when you have sensors that can identify the following:

- Who is behind the wheel of your trucks and operating your equipment

- Trailer environment conditions like humidity and temperature

- A vehicle’s carbon emissions and tire pressure

- Trailer load capacity

- When job site trailer doors open and close

- Concrete sensors that monitor the hardness of ready-mix and standard concrete

- Power take-off equipment operation, like raising crane arms, lifting dump truck boxes, and bulldozer movement

- Fuel level

- Asset safety by monitoring smart lock status when not in use

The Future of Construction

A Transparency Market Research study estimates that construction industry IoT investment in 2021 totaled around $7.6 billion USD and predicts it will grow to $34 billion USD by 2031. Many construction-related priorities like safety, security, productivity, and machine efficiency are ideally suited for monitoring with connected telematics devices, data processing platforms, and integrated business applications like Jonas Software Dispatch Scheduler

Are you looking for information on how to keep your construction fleet assets and projects moving forward? Visit our construction industry solutions web page or contact us.