As a fleet manager, you’re under a lot of pressure to make the right choices. No one’s right all the time. However, one way to make better, more purposeful decisions is to track your fleet’s metrics.

1. Miles Traveled

A preventative maintenance (PM) schedule can help you track and analyze your fleet’s health—something that’s well worth doing since a well-maintained vehicle burns less fuel and breaks down less often.

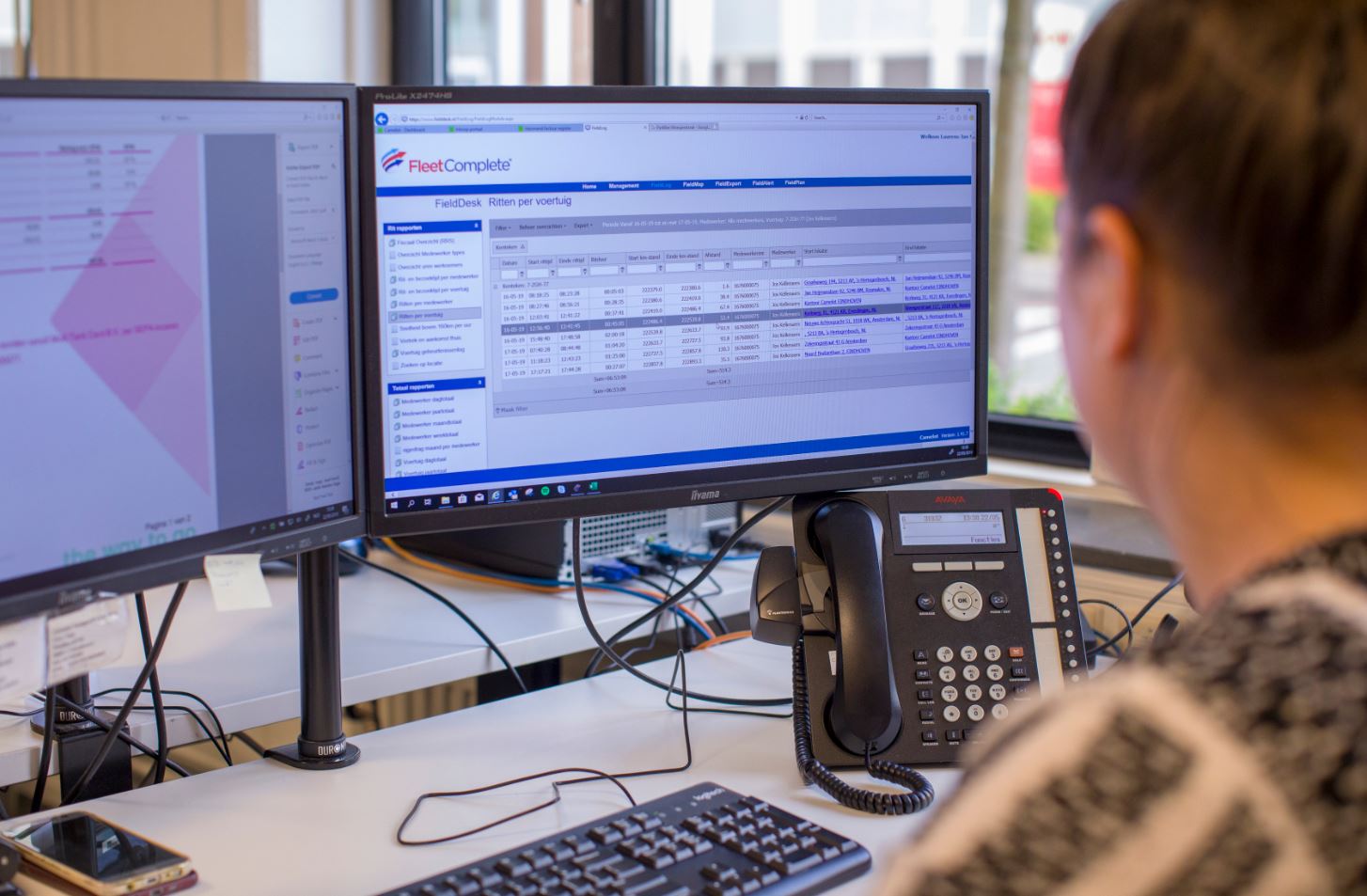

Like all things in life, good organization is key to getting the most benefits from PM. Recording miles traveled can help you plan and schedule maintenance checks. Utilize fleet management software to help with automatic trip data collection and set up alerts so you and your team complete maintenance checks on time.

2. Inspection Results

Checking your Daily Vehicle Inspection Reports (DVIR) will help you keep your fleet compliant and catch problems early, before they snowball into larger, more costly issues.

Analyzing data collectively also gives you a bird’s-eye view of your assets, which makes it easier to spot common problems across your fleet. Seeing these patterns can help you plan and implement preventative maintenance measures faster.

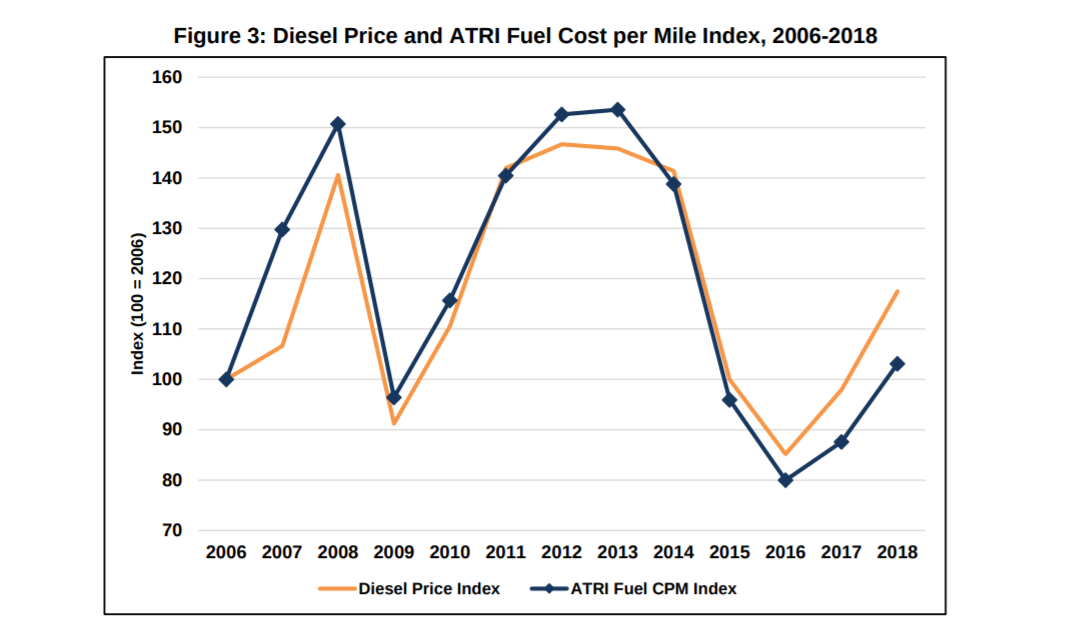

3. Fuel Costs

According to the American Transport Research Institute, fuel prices have risen a whopping 17.7% over the past ten years—with a sharp upward spike since 2016.

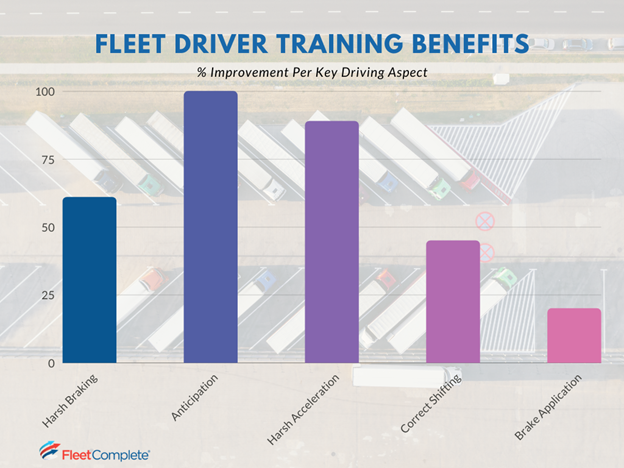

Tracking fuel consumption and monitoring cost-per-mile expenses can give you valuable insight into the performance of your vehicles, as well as the performance of the drivers themselves. With this data, you’ll also be able to make adjustments or provide training to help lower fuel consumption across your fleet.

For additional insight into your team’s habits, track fuel stats with GPS fleet management software, which can alert you to issues like aggressive driving, or staff using vehicles for personal use. Tracking software also collects data automatically—meaning you and your drivers don’t need to worry about manual data entry or sorting through paper receipts.

4. Repair Times

The costs of downtime can quickly add up. Keep an eye on how long assets spend with the mechanic by tracking repair times—whether they’re being done in-house, or via a third party.

Fleet management software can help you keep a tight grip on things like completion dates and notifications from the maintenance team. If repairs are being done in-house, you can also use this data to measure your repair team’s productivity and provide training and feedback if progress falls below what’s expected.

5. Odometer Readings

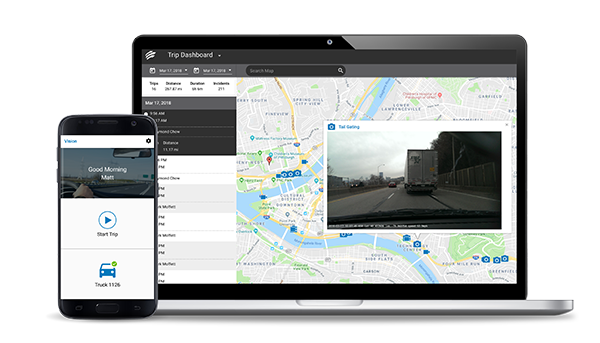

Your fleet’s odometers contain loads of useful data. Most PM tasks are based on mileage per hour, so collecting each vehicle’s stats can help you stay on track with timely maintenance checks. You can also use this data to monitor your drivers’ performance and to ensure they’re following set routes.

For the best results, make sure you schedule regular odometer updates. Automate this data collection via fleet management software instead of collecting it manually—it reduces the chance of error and is far less time-consuming.

6. Asset Use

It’s important you get the most use out of the assets you have. Collecting information about your vehicle usage (miles traveled per day) can help you optimize your fleet’s performance and help you stay on track with things like maintenance schedules.

You may discover underused assets that would be better off being sold—or find out your current fleet is struggling to meet demands, which could result in delays or downtime. In this case, you should look into expanding your fleet.

7. Vehicle Turnover

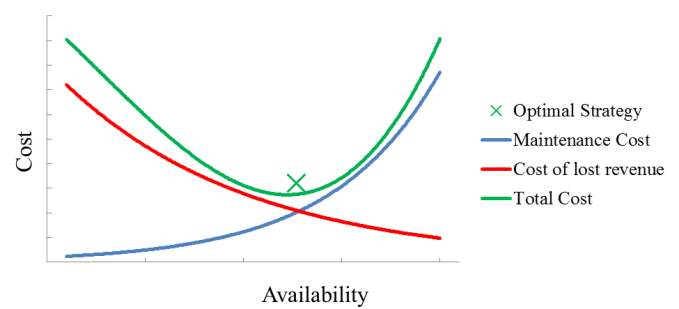

No manager looks forward to replacing assets. However, while it is expensive to buy a new vehicle, the cumulative costs of running an old fleet soon add up when you factor in things like repairs and downtime.

As the graph below shows, keeping assets operating longer than they should causes costs to rise. It also means you run the risk of using vehicles that aren’t compliant with current safety and emission regulations.

Fleet management software can help you stay on top of your vehicle replacement schedule and find the right time to replace vehicles. Make sure you know which vehicles are in operation, which ones have a few years left, and those that will soon need to be replaced.

Fuel economy improvements in more modern vehicles may also prompt you to upgrade. As Mike Roeth, executive director of the North American Council for Freight Efficiency, told Trucks.com, “From 2012 to 2017, we saw a lot better fuel economy year over year. Overall, new trucks are a third more fuel-efficient than older ones.”

Kenny Vieth, president of ACT Research, added: “Buying new, higher quality equipment is a great way to improve efficiency and avoid paying so much in taxes.”

8. Inventory Levels

Tracking your inventory can help you avoid out-of-stock events that could incur big costs when you factor in downtime and replacement parts.

Track inventory levels in an online database. Knowing your current stock levels helps you plan ahead. If a vehicle does need repairs, you have everything you need to get it on the road again, fast.

Understanding the true cost of running your fleet allows you to confidently make data-driven decisions about your business. If you want to optimize your fleet operations by always having the necessary data to make key decisions, learn more by requesting a Powerfleet (formerly Fleet Complete) demo.