There’s a popular saying in business that goes: “If you don’t measure it, you can’t improve it,” and the same couldn’t be truer for fleet management. Knowing where your money is going is the best way to start saving.

For many businesses 2020 was challenging, to say the least, with COVID-19 wreaking havoc on the global economy. If you’re looking to take a more cautious approach to spending, we’re here to show you how telematics gives you true oversight of your fleet’s costs.

Monitor Fuel Usage and Driver Behavior

Fuel is one of your fleet’s biggest expenditures, so it makes sense to keep a close eye on usage.

The first step? Measuring driver efficiency.

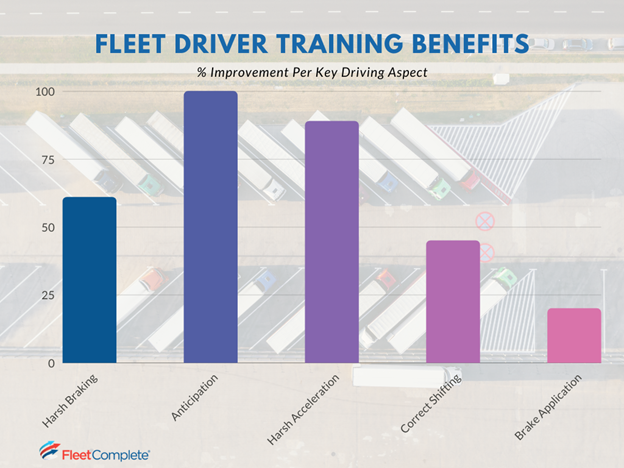

GPS fleet management software tracks things like harsh braking, idling, sharp cornering, and other behaviors that are proven to burn fuel faster. Armed with this information, fleet managers can create targeted training programs, aimed at righting problem habits.

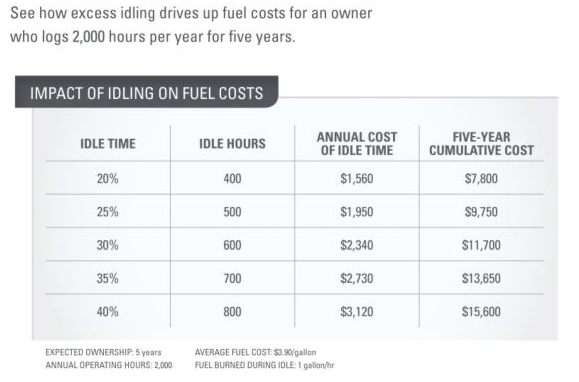

Every driver leaves the engine running from time-to-time. But day after day, year after year, these costs add up (Image Source).

Reward Good Performance

It’s not just about picking up on problems. Fleet data can also be used to reward good driving.

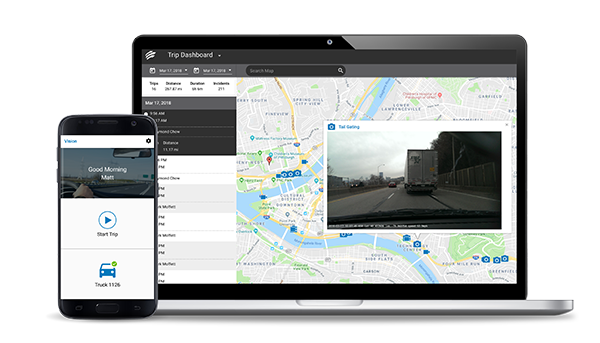

Positive reinforcement is a sure-fire way to motivate the wider team. With VisionAI Hub, Powerfleet’s (formerly Fleet Complete) video dash-camera solution, you can provide customized coaching thanks to live in-cab feedback, video replay, and leaderboards. Personalized scorecards allow drivers to see where there’s room for improvement and how their driving measures up with that of their colleagues.

“Before implementing the system, we could not evaluate driving behavior. I was wondering how to save fuel costs. And then I recognized that the only solution would be a GPS system,” says Günter Flicker, Fleet Manager at J.R. Company.

As well as helping keep fuel costs down, constantly working towards improving driver behavior has the added benefit of reducing vehicle wear and tear, and lowering the chances of a fleet vehicle being involved in a road accident.

Monitor Maintenance Schedules and Save on Unplanned Downtime

When a vehicle breaks down, the costs are big. There’s a delay to that current job, plus the cost of paying a driver who’s idle, not to mention the cost of sending out a replacement vehicle. That’s not to mention knock-on effects, like missed business because a vehicle is unexpectedly off the road.

“Many operators put the cost of having a vehicle off the road as being in the hundreds, if not thousands (of dollars) per day. Therefore, it is surprising that many fleets aren’t taking more positive action to manage their exposure. It is almost a stealth cost,” says Mark Cartwright, head of vans and logistics buyers at FTA.

Downtime is an expense many fleet companies are unaware of. Make it a priority to do everything you can to avoid it. Here are three ways to measure and save:

1. Set up a Preventative Maintenance Schedule

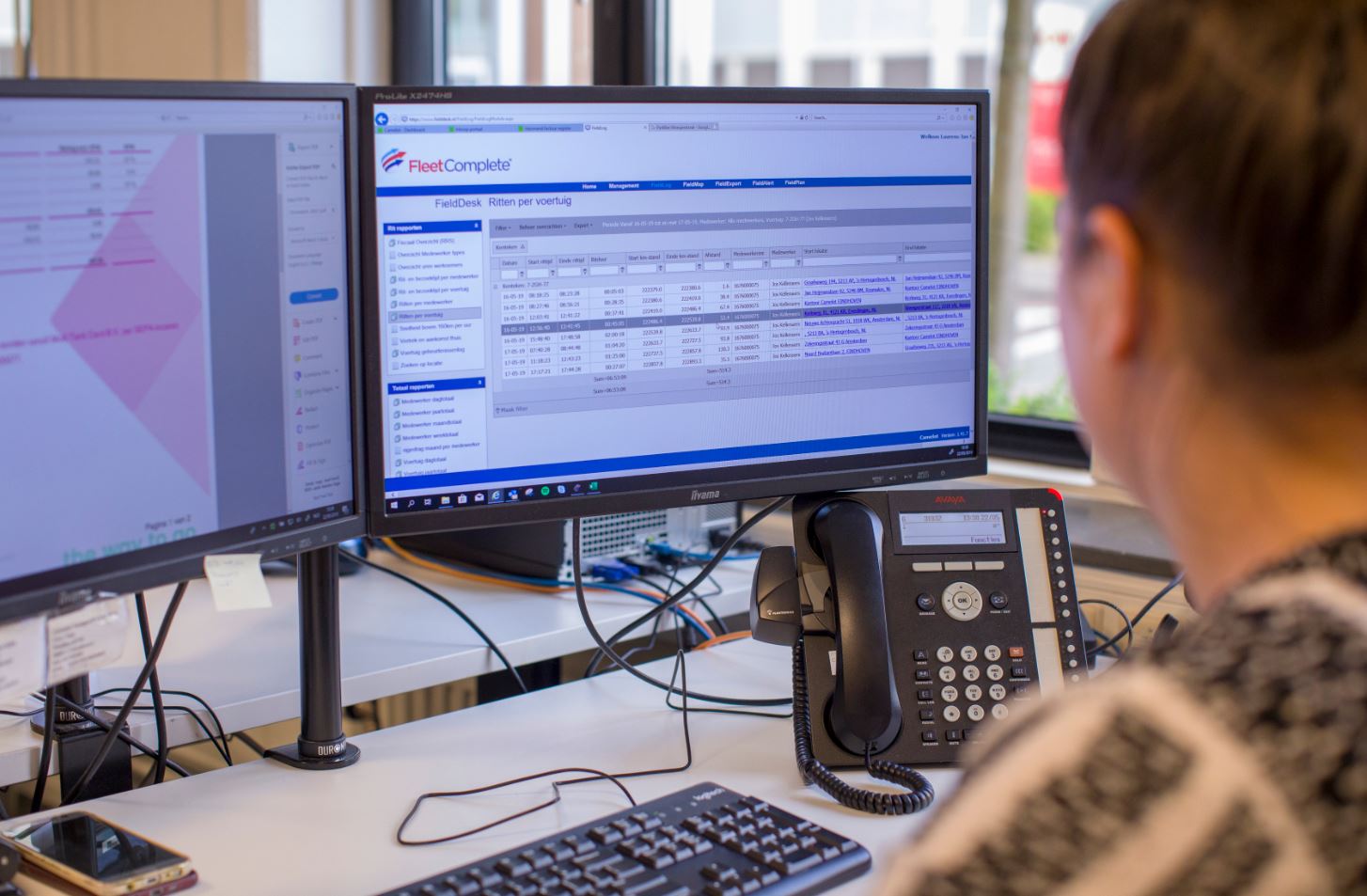

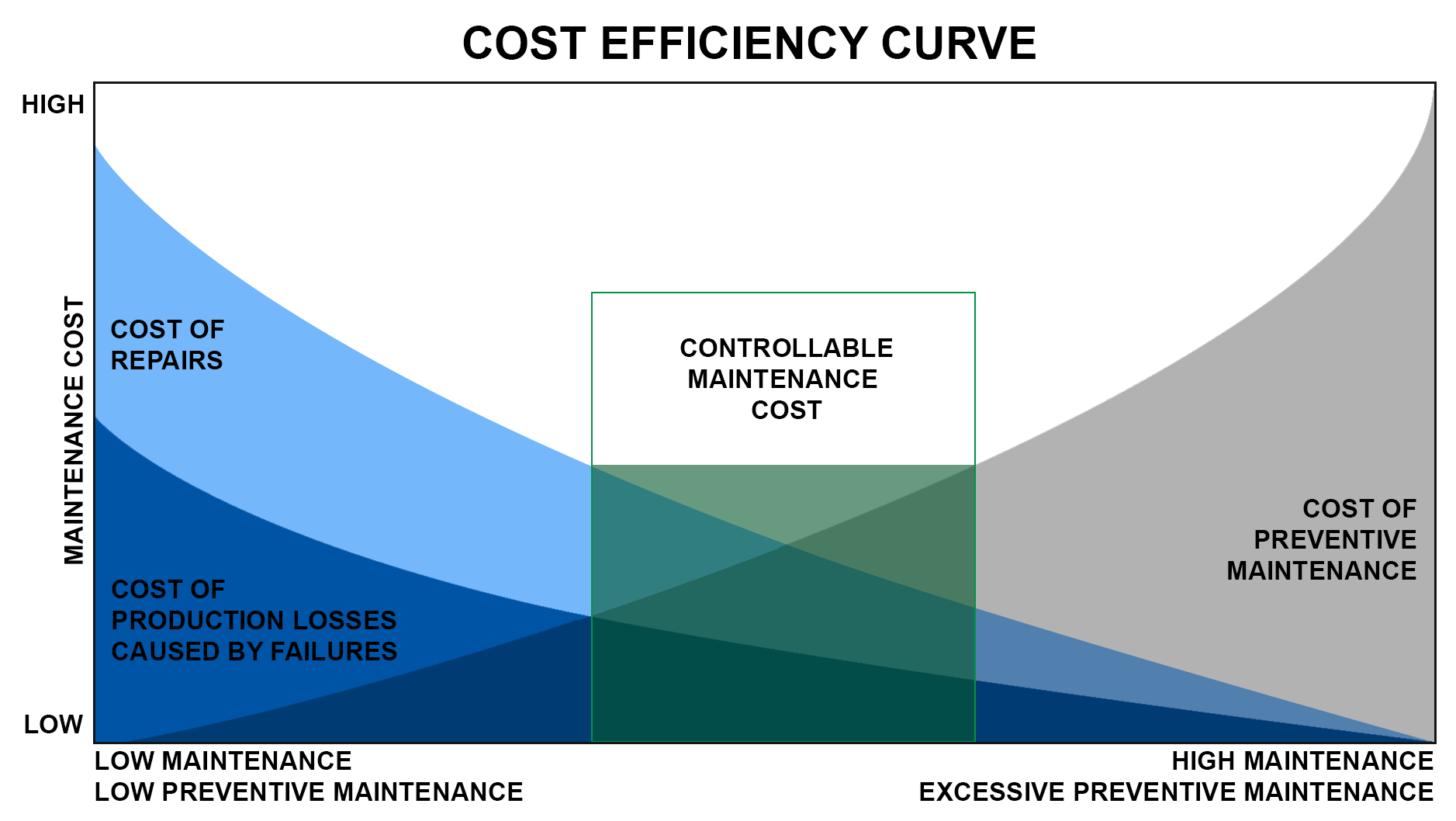

A preventative maintenance (PM) schedule is the best way to proactively monitor your fleet’s health. With alerts, fleet management software can help you stick to your schedule, spot issues early on, and catch them before they turn into costly problems.

Telematics can help you find that preventative maintenance sweet spot (Image Source).

1. Create a Vehicle Replacement Plan

New vehicles are expensive, but the costs of running an old, unreliable fleet stack up. Modern vehicles are more fuel-efficient, they break down less, and they’re often greener to run and nicer to drive. With telematics, you can see which vehicles need to be replaced.

2. Use GPS Tracking Software

GPS tracking can automatically tell you how far a vehicle has traveled—meaning no need for receipts or driver logs. With this information, you can set up telematics system alerts to remind you every time a set distance has been traveled.

Improve Efficiency with Route Planning

Taking a wrong turn, getting stuck in traffic, or simply taking an inefficient route means wasted time and fuel.

Throughout multiple trips, these costs add up.

With fleet management software, you can plan routes more efficiently, re-route drivers away from bad traffic or accidents, and fine-tune the sequence of destinations/tasks at the touch of a button—the system finds a route that lets your drivers spend the least time and fuel, which directly saves you money.

How to Use Powerfleet’s (formerly Fleet Complete) ROI Calculator

Curious to know how much you could save with fleet management software?

Try our ROI calculator out for size. Simply enter in the details as accurately as you can (approximations are fine) to find out your monthly and annual savings and expenditure, both with and without Powerfleet (formerly Fleet Complete).

If you want to find out how calculating fleet costs can help you save money, try our ROI calculator then request a Powerfleet (formerly Fleet Complete) demo and take it out for a spin in the real world.