What is the Condition of Your Tires?

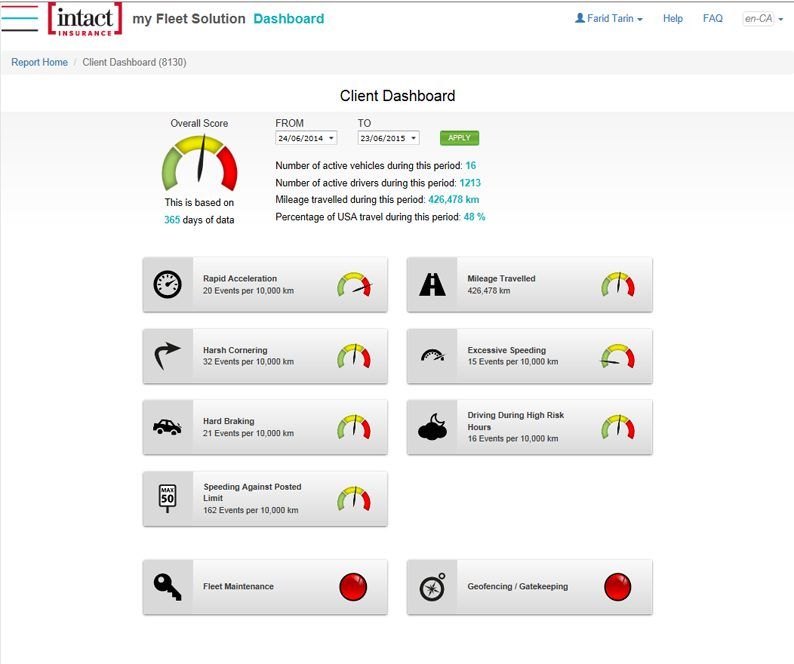

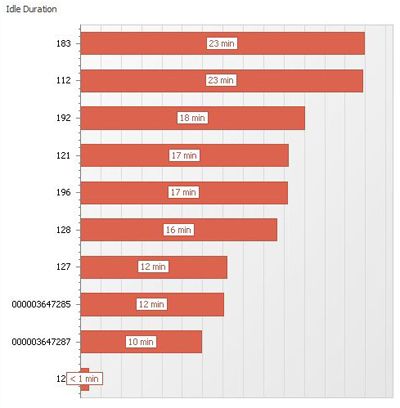

Roadcheck 2016 is scheduled to take place in every jurisdiction across North America between June 7-9, 2016. This year the focus will be on tires, in addition to the typical driver and vehicle issues found during roadside inspections. With an effective Fleet Management system, you can create unique maintenance items and receive alerts when the maintenance is due.

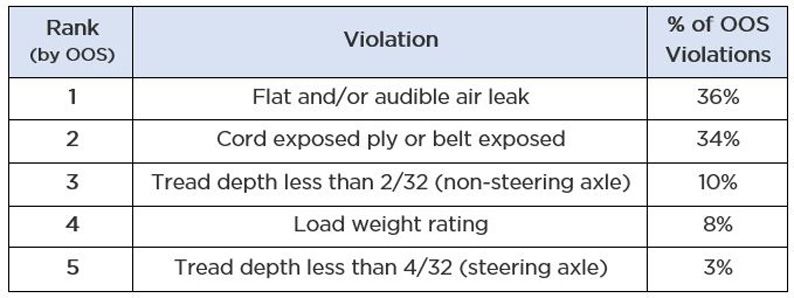

Looking Back at 2015 Results

The data collected from 2015 clearly shows tires continue to be a leading cause of roadside violations and out of service defects during these inspections. As you can see by the “top 5” from last year, flat tires, exposed cord, and tread depth violations continue to lead the way when it comes to out of service issues (OOS).

Tire OOS Criteria

In light of this focus for Roadcheck 2016, it is recommended that you understand the Commercial Vehicle Safety Alliance (CVSA) OOS criteria, specific to tires, in preparation for this 3-day safety blitz.

The most common reason commercial motor vehicles (CMVs) are placed OOS for tires is due to when the unit has a flat or under inflated tire, based on the load it is carrying. Flat tires should not be driven on except if you are merely trying to get off the roadway. Extended operation on a flat tire frequently results in unsafe conditions for all motorists, such as when a tire eventually disintegrates, leaving debris all over a highway. Even worse is when blown tires catch fire and become very difficult to extinguish. Obviously, flats happen and cannot always be predicted, however, a thorough pre, in-transit and post trip inspection can often catch cuts, bulges, sidewall separations, and foreign objects before the tire fails.

Any flat will result in an OOS violation that has to be repaired immediately, or the CMV will be placed out of service. Repairs during non-business hours, at inspection stations and roadside, are much more expensive and time-consuming than those at the truck terminal or a tire shop. Spend the time to look critically at your tires when you are doing your pre and post trip inspections, otherwise, be ready to be detained from delivering your load.

Tread Depth Standards

Tread depth must be no less than 4/32” for a steering axle tire, and 2/32” for the remaining tires. Those measurements must be taken in a major tread groove. Common sense dictates that worn tires will not deteriorate overnight, so again the driver inspection is key as tires incur extended mileage. Tire tread depth gauges are the most accurate way to measure tread depth. One warning is that studies routinely show tread depths at or close to the legal minimums will not be able to properly channel water, which creates a dangerous hydroplaning situation. More tread depth is better to maintain contact with the road surface and to enhance safety for you and those you share the roadway with.

Regulations also prohibit re-grooved, re-capped or re-treaded tires on the front wheels of all buses and re-grooved tires with a load carrying capacity equal to or greater than 2,232 kgs cannot be used on the front of any truck or truck tractor.

Alignment and Tire Wear

Keep vehicle suspension in alignment as improper alignment will rapidly wear tires. Maintain proper air pressure. A 10% PSI under inflation can result in a 20% decrease in tire life, and tires can lose 3 PSI per month due to normal air migration. Tires will also run five degrees hotter for every PSI of under inflation due to flexing. Mismatching air pressure in dual assemblies of as little as five PSI can change the tire circumference. At over 100,000 km that would be the equivalent of dragging the underinflated tire nearly 250 km.

Finally, watch the load restrictions on the tires as well, especially if operating underweight permits that exceed normal maximums. You may have a weight permit to exceed normal statutory limits, but you likely do not have the tires to transmit that weight safely without damaging your tires.

Final Thoughts on Tire Inspections

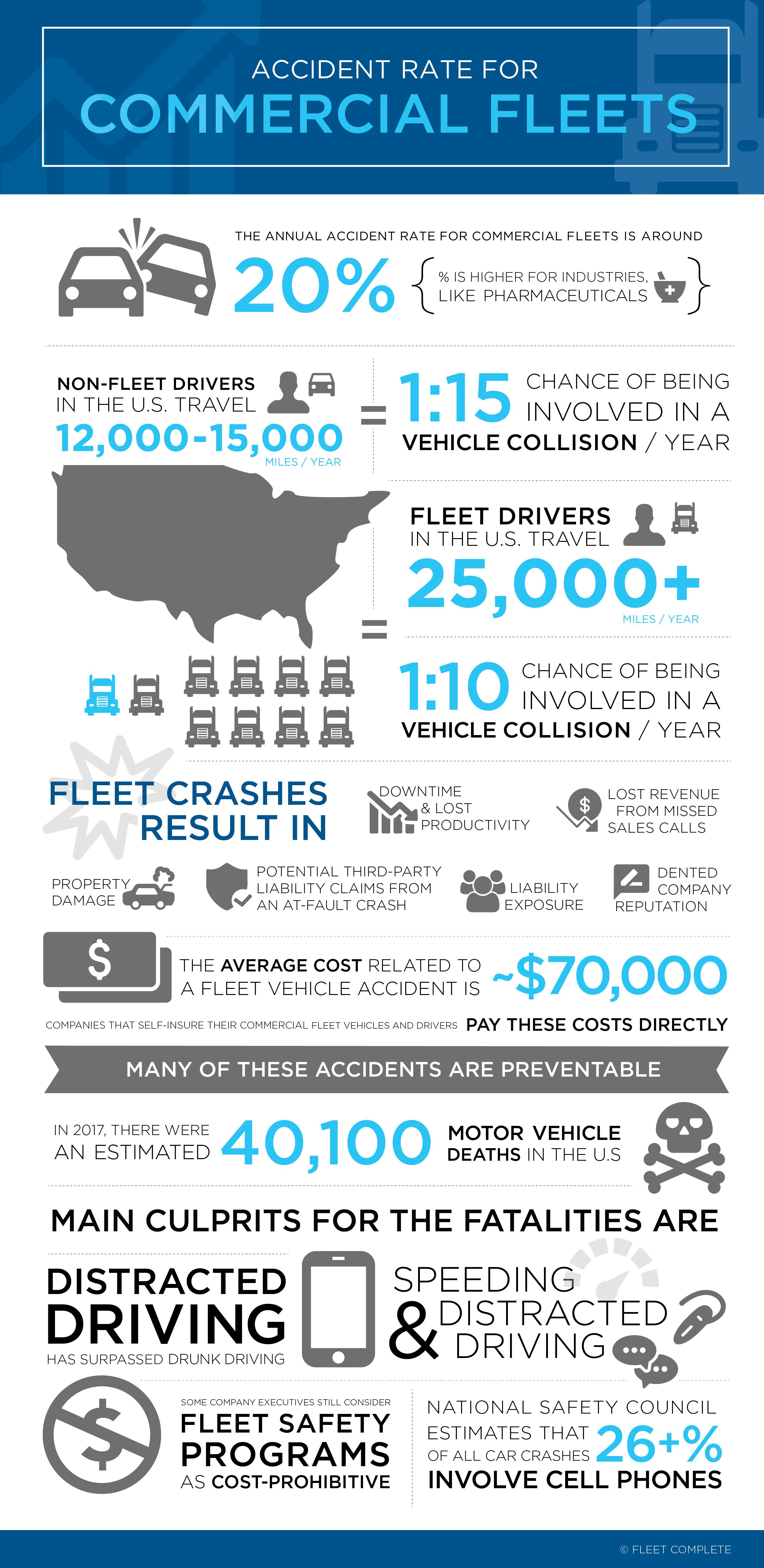

Well, maintained tires are your best insurance against costly repairs and damages that can result in crashes. While replacement is expensive, the alternative could have you wishing you had invested the time and money when something unfortunate happens. Roadside inspectors are especially critical of tire issues. The results of tire neglect and the associated costs in equipment, injuries, and lives are simply not worth.

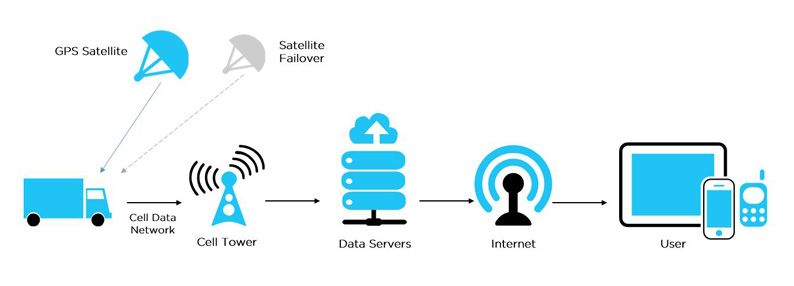

Is highly recommended that you proactively manage the maintenance of your vehicles with a Fleet Management system. Get in touch with our specialists and find out how our solutions will help you get ready for Roadcheck.